Coil Gun Development

The purpose of this project is to design and develop a coil gun system which Missouri S&T can use as a demonstration tool during tours of the department for the purpose of recruiting prospective students. Major goals for this project included ease-of-use, relatively low cost, portability, long range, and high accuracy. The safety of both the operators and observers is a major concern and is placed at the forefront of all design decisions made.

Teamwork.

To design a system that performs to these standards, I worked closely with a team of engineers that exhibited expertise in multiple fields of study. Starting with the mechanical design, the structural basis of the system required multiple designed parts that maintained functionality and portability. To make these parts finite element analysis, materials sciences, and computer-aided design were used to complete the mechanical design of the coil gun. Developing the hardware required knowledge of circuit development/analysis, as well as working with integrated circuits and other off-the-shelf components that were used in the design. Often debugging and testing of custom hardware was needed. The hardware required a software element to enable full functionality. C++ was used to allow for rapid analysis and response of feedback from the rest of the system. It should be noted that the creation of a coil gun is inherently a dangerous project. Care was taken to minimize the harm to its users and any bystanders. This device is only intended to serve as a demonstration of electromagnetic principles and will not be used to injure anyone. To this effect development of testing plans, safety standards, standard operating procedures, and validation tests were carried out to ensure that the process of creating a coil gun was safe.

Brady Davis: Team Lead and Power Electronics Lead

Grant Brinker: Control Hardware Lead

Evan Seabaugh: Mechanical Lead

Maxwell Ryan: Verification and Validation Lead

Alex Wortmann: Control Software Lead

Goals and Methods.

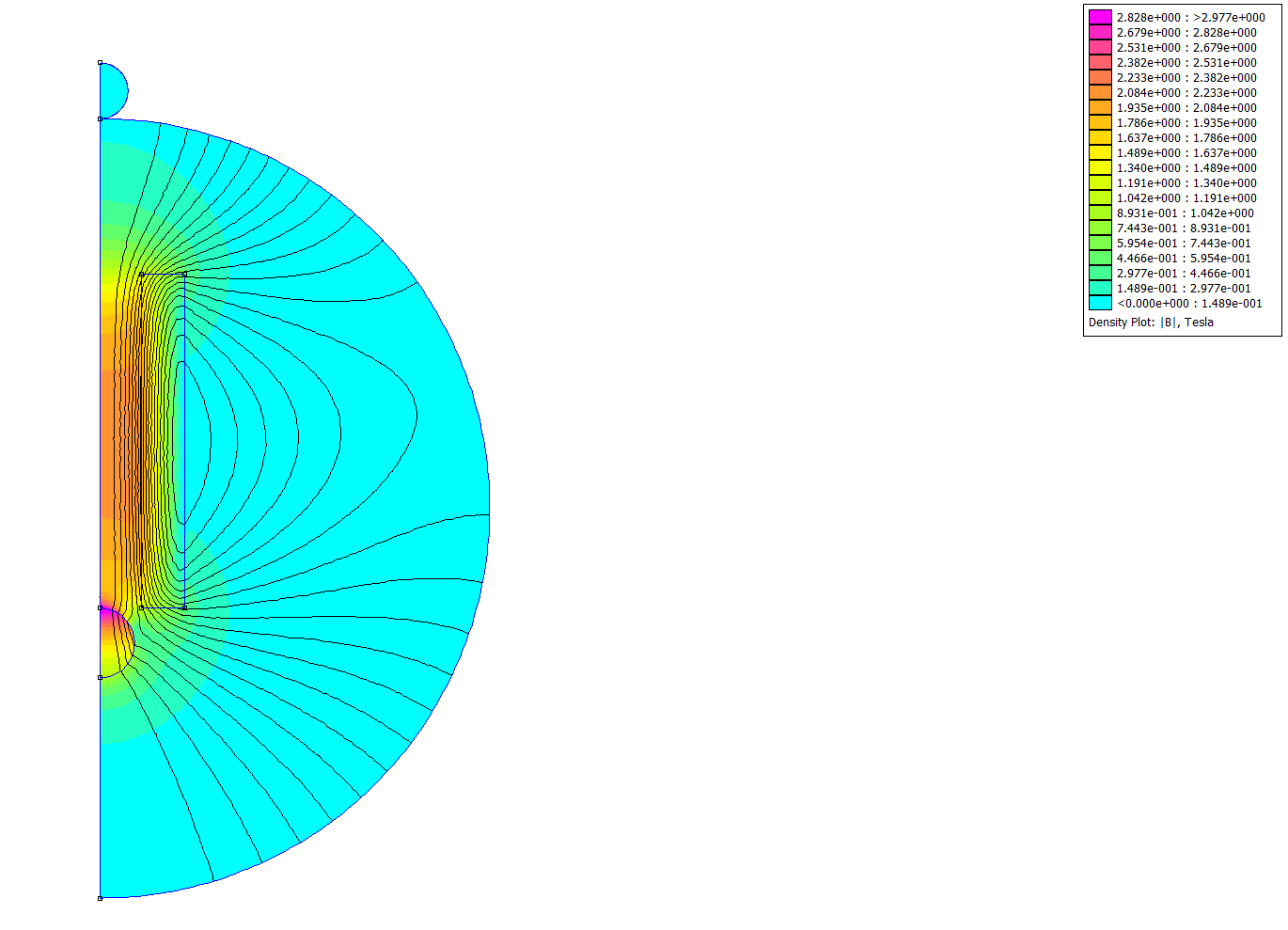

In the original proposal, the goals for the project were to develop a coil gun which maximizes accuracy and distance, minimizes cost, and acts as a safe yet effective demonstration tool for the ECE Department. To accomplish these goals, the project was designed with six coil stages, a 32mF capacitor bank, a 380V maximum charge, high-power high-speed MOSFETs, and an aesthetically pleasing 3D printed body, all of which are detachable from the AC-DC power supply.

Goal 1: Conduct Research

Developing a custom coil gun required extensive initial research by the design team. Every member of the group played a role in becoming a “subject matter expert” regarding one of the aspects of the project. Most notably are the calculations and simulations needed to make design decisions. Things such as the configuration of the coils, the coil timing, and magnetic flux optimization required significant resources to make decisions.

Goal 2: Finalize List of Hardware Components

The team developed a finalized Bill of Materials based on information that was gathered in the research phase. Materials for testing and development were procured primarily from online distributors such as Digikey.

Goal 3: Design

The following section details the various high-level systems that were used for coil gun development. See Technical Approach and Results for more detailed description. Budgetary restraints were a major challenge for these tasks because during system testing, there were several components that were damaged and had to be replaced.

Goal 4: Prototyping

Each custom component of the design was prototyped, and later realized with a custom printed circuit board. This allowed our prototype units to be run under close-to-expected conditions. Prototyping in this fashion allowed us to design and manufacture second revision boards which helped to make system changes.

Goal 5: Verification and Validation

Verification happened on the component and system levels. Testing plans were developed using inspiration from organizations such as the NRA and the US military, or from standard work procedures for high energy and kinetic devices. Lab equipment was used to verify each component described above in the Design section. The subsystem-level tests took components and group them together based on function (coil and barrel, capacitor bank charging/discharging circuit, it, etc).

Hardware.

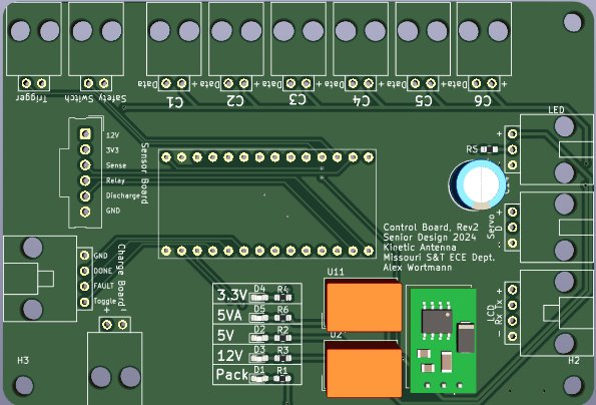

Control Board

The Control Board handles several logic-level functions such as receiving the trigger signal, sending the fire, charge, and discharge signals, receiving voltage measurements, and displaying information on the LCD. The Charging Board interfaces with the power supply and receives the signal from the Control Board to charge the capacitor bank. The capacitor bank is housed on its own PCBs due to its size and copper requirements. Lastly, the Coil Boards house the coils themselves and MOSFETs to toggle current flow, flyback diodes to prevent large transients, and gate drivers for operating the FETs. The control board consists of a Teensy 4.0 microcontroller, switching DC power supplies, and connectors to interface with other boards within the system, as well as the trigger and LCD. Power for the control board and other logic-level circuitry is supplied by an on-system battery.

In revision 1, this board also contained the gate driver circuitry used to control the MOSFETS for toggling the coils. However, it was found that the distance between the control board and coil board creates a large inductance loop which causes ringing, distortion, and in severe cases, repeated toggling of the FETs, resulting in system failure. Because of this, the gate drivers were moved to the coil board for Revision 2.

Charging board

The AC-DC rectifier receives 120V, 15A, 60Hz from a wall outlet and converts it 24V DC for high-power systems within the gun. This supply is directly interfaced with by the Charging Board. The primary functionality of this board is handled by the LT3751EFE#PBF charging IC. Most of the components on this board are external circuitry for the charging IC which receives the 24V supply and uses a transformer to increase it to much higher voltages for the capacitor bank. The remaining circuitry on this board is a set of switches for controlling the voltage level to charge to and interfaces. Once the board was manufactured and tested, its operation was incredibly reliable. Thus, no second revision was required for the board.

Capacitor Board

The capacitor bank was divided into two large PCBs, each containing 16 1mF capacitors to lower the circuits ESR for the best discharge performance.

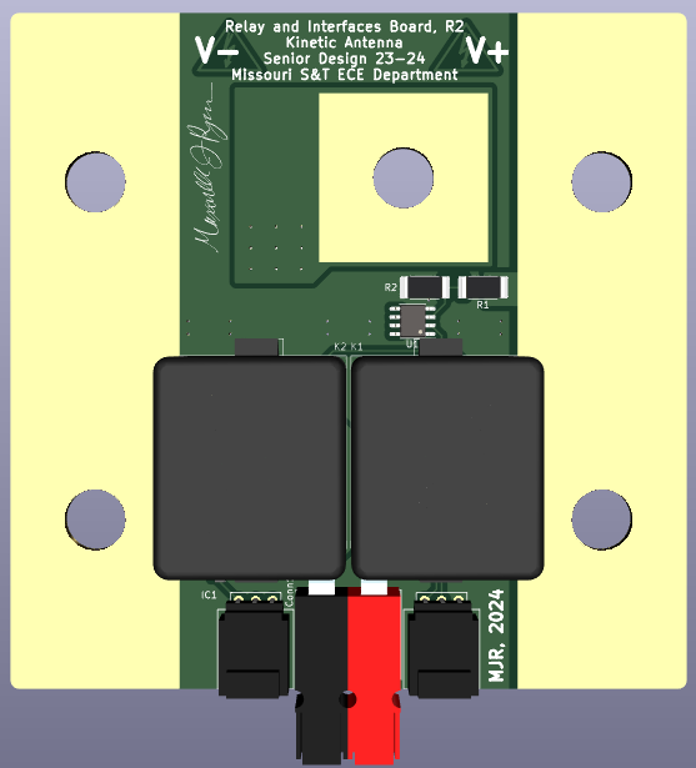

Relay Board

The Relay board utilizes two relays to cut off high voltage from the connections between the charging dock and the gun. Control of this is accomplished through a relay driver IC and a logic signal from the microcontroller. The board also has an N-Channel MOSFET and gate driver to low-side toggle the power resistors for safe, fast discharging of the capacitor bank. The power resistors are 4 1kΩ 150W resistors in parallel for an effective 250Ω of resistance. Lastly, the board contains a simple voltage divider and op amp buffer circuit for measuring voltage on the capacitor bank.

Apart from a new op amp which has the same package as the original one chosen, the Revision 2 board is essentially the same as the first revision.

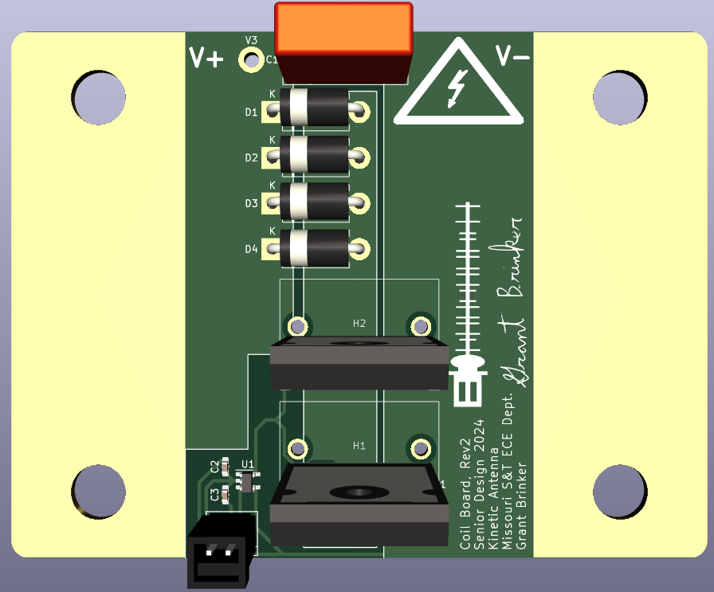

Coil Firing Board

The Coil Boards contain the coils themselves and the circuitry necessary to toggle them. Two N-Channel MOSFETs with large heatsinks are utilized to handle the amount up to 800A instantaneously traveling through the coil. A gate driver is used to control them, and an in-line resistor is used to prevent over-currents from damaging the gate driver. Flyback diodes are used in parallel with the coil to prevent large negative voltage swings from damaging the FETs. Lastly, a 1uF capacitor is placed between power and ground to reduce the inductance loop in the system.

As mentioned previously, the gate drivers were initially on the Control Board. However, inductance loops forced the team to move these to the Control Board instead. The first revision also featured a Y-rated capacitor and separated ground planes. However, voltage referencing issues caused this to be removed. The 1uF capacitor was also added for the second revision.

Mechanical Structure.

The mechanical structure was comprised of 40+ parts. All components were fixed to an internal structure which was followed by a second outer casing that covered all high voltage areas. This helped create a product that was stylish while remaining functional and safe for the user. This 2-layer design was bifurcated into multiple subsections that could be 3D printed in a 256mm x 256mm x 256mm area. These sections were then joined together using a combination of threaded heat inserts and dove tail connections between parts. This allowed the entire assembly to be quickly iterated if changes needed to be made to any internal circuitry. The design enclosed the barrel and each coil in a shell that maintained even spacing while providing structure to the system. This consistent spacing ensured each stage of the coil gun was properly timed. The breach system was comprised of a servo that blocked the barrel from the front while a bolt carrier secured the projectile from the back. This allowed for precise timing of the projectile release to produce consistent firing results.

Below is an interactive cutaway model of the coil gun assembly:

Find out more.

More details can be found in the Final report available HERE