3D Printing

The world of 3D printing has always fascinated me. One must think completely differently when designing a part for additive vs subtractive manufacturing. I was eager to learn this process. I got my ender 3 pro and immediately absorbed what I could from sources online and the students in my university with experience. Quickly my appetite for printing faster and accurate models guided me towards learning what was going on behind the scenes in the printer’s firmware, learning how to optimize slicing software, and learning to use better modeling approaches for this manufacturing process. I learned to improve the printer I would need full control of every aspect and my focus began on rebuilding the printer from the ground up.

Mechanical.

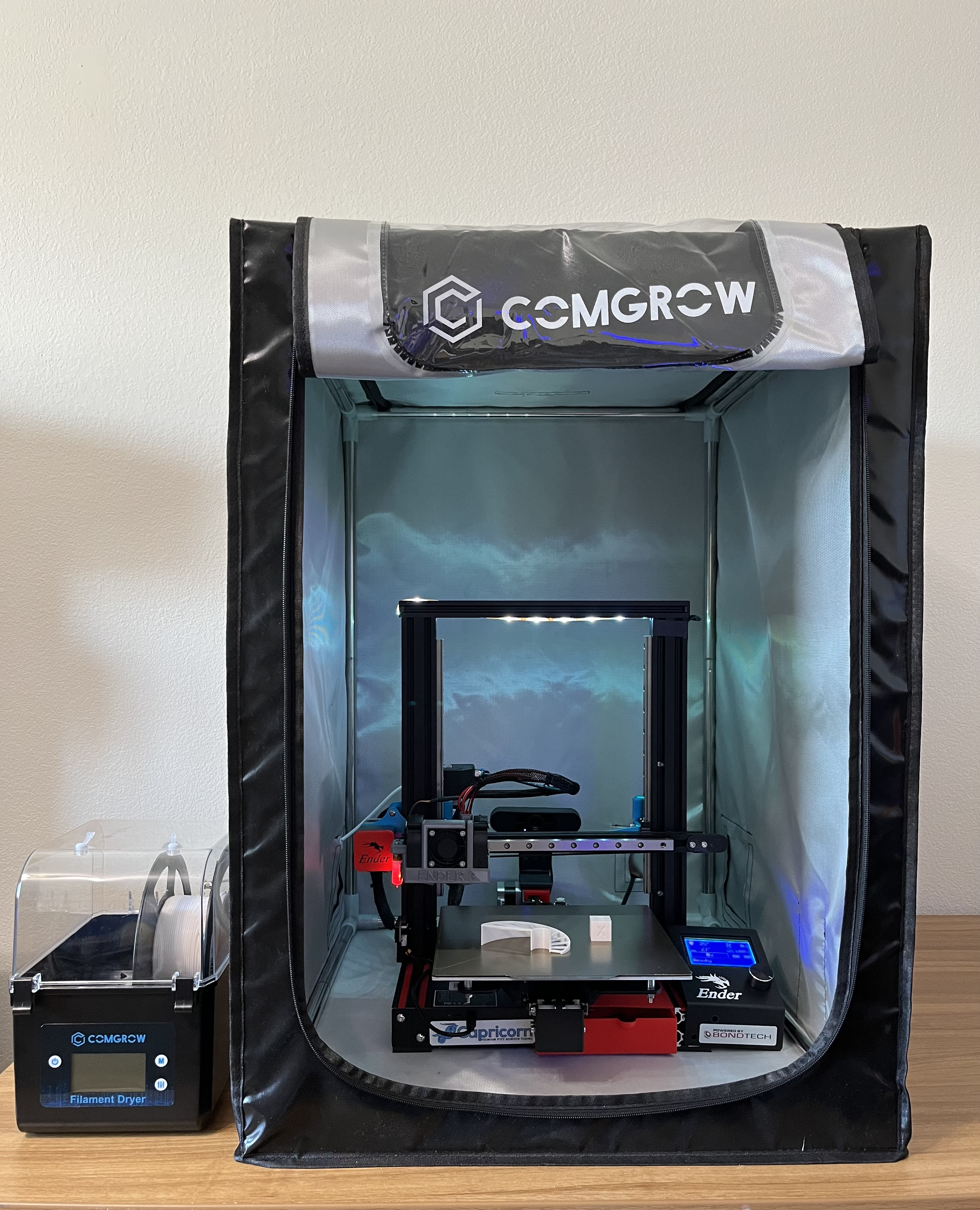

The project started with a reimagined chassis layout:

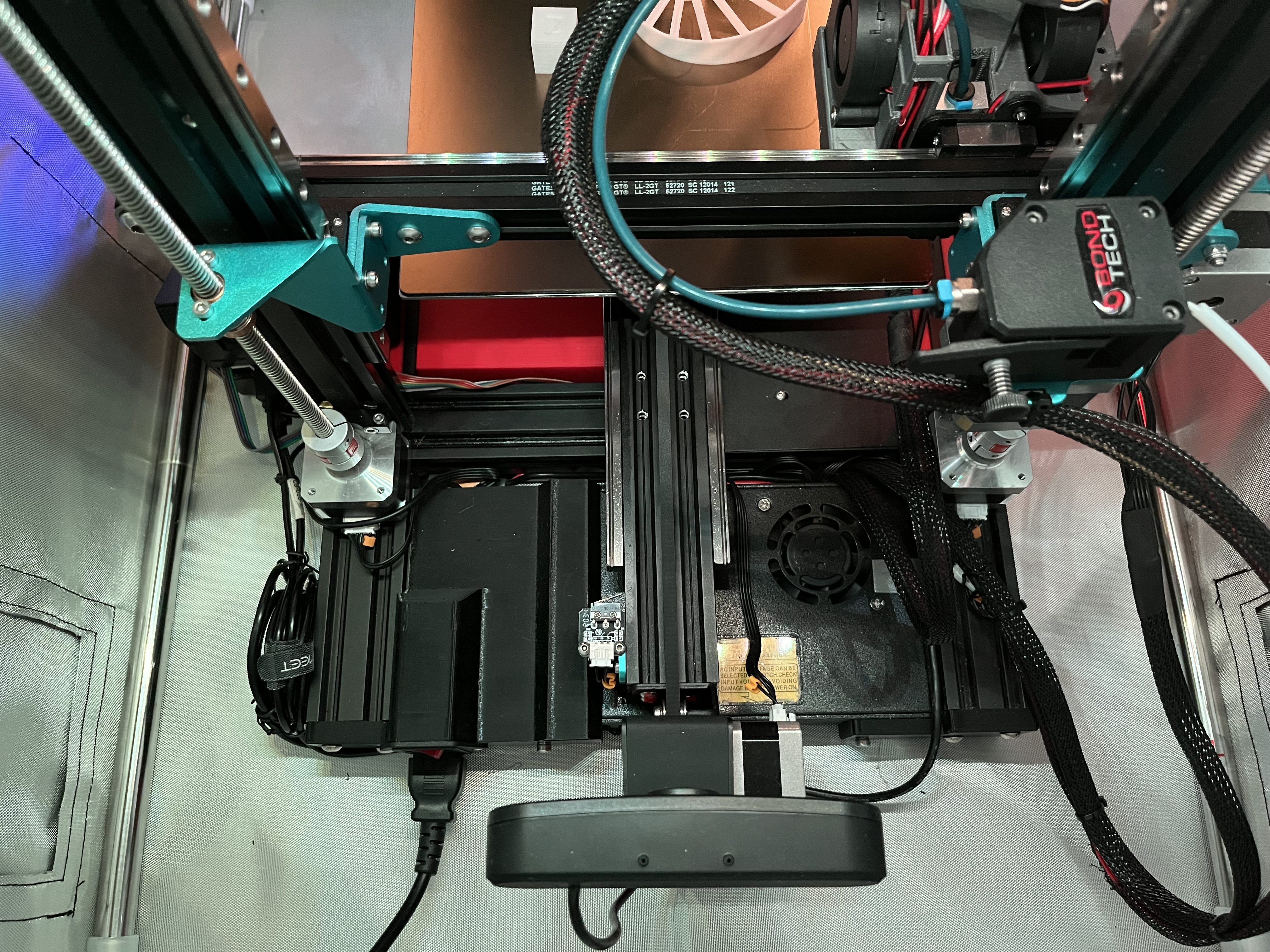

- The power supply was moved below the Y-axis with a custom designed bracket to enclose the power plug and the supply.

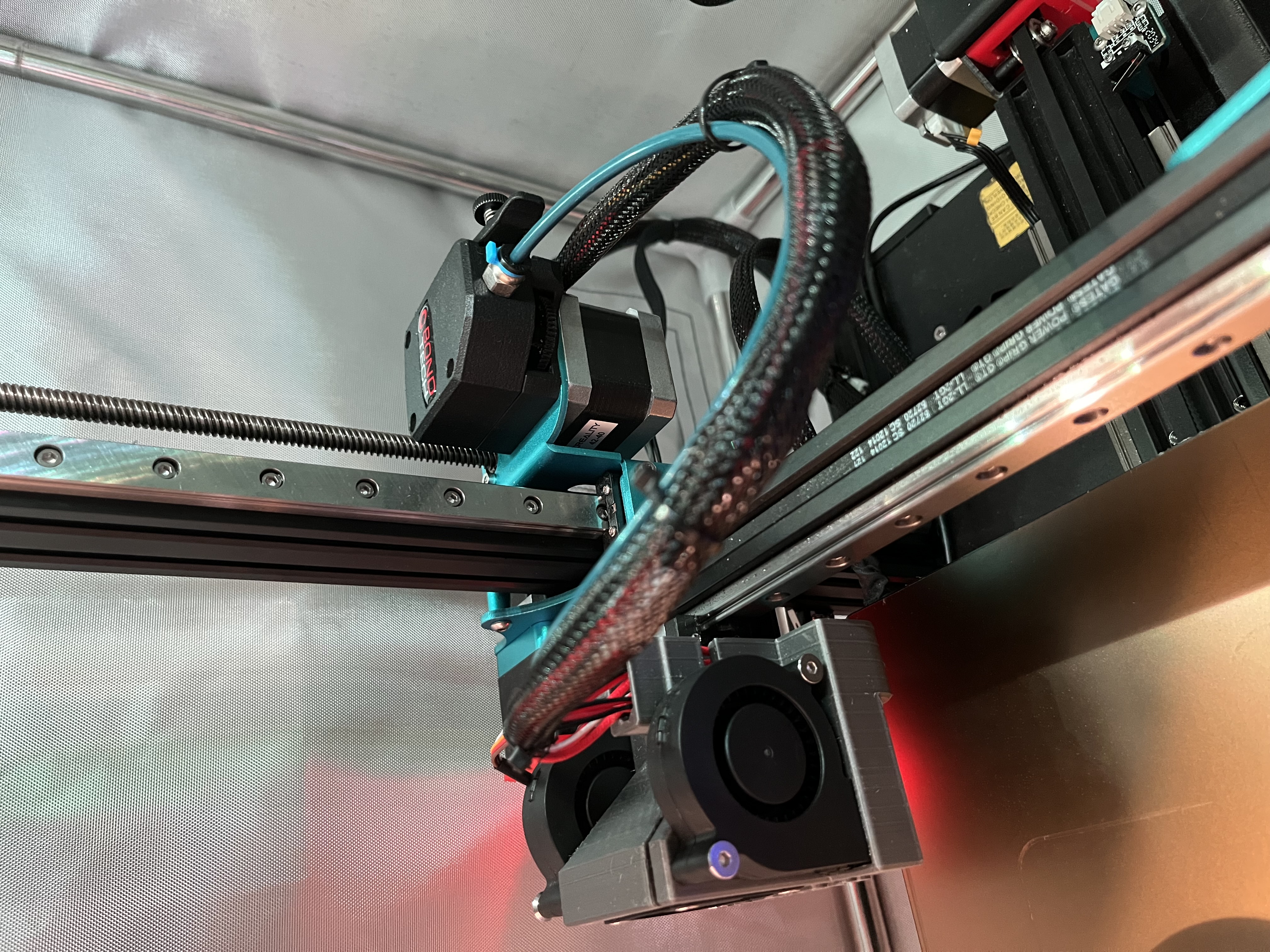

- A second Z-axis lead screw and matching stepper motor was added to properly support the X-axis apparatus and prevent it from sagging when printing.

- A modified Z-axis screw nut with spring tensioning was installed on each screw to eliminate backlash.

- The V-slot rollers wheels were replaced with linear rails on the X, Y and Z axes for more precise and robust movement.

- The build plate adjustment springs were removed and replaced with custom rigid bed mounts to eliminate build plate movement after a software mesh is used to level it.

- A more robust metal dual gear extruder replaced the original single gear plastic extruder to help prevent filament slipping under load and provide more precise control over extrusion.

- The original magnetic bed surface was stripped off and replaced with a PEI coated print surface to decrease Y-axis weight and increase the first layer adhesion.

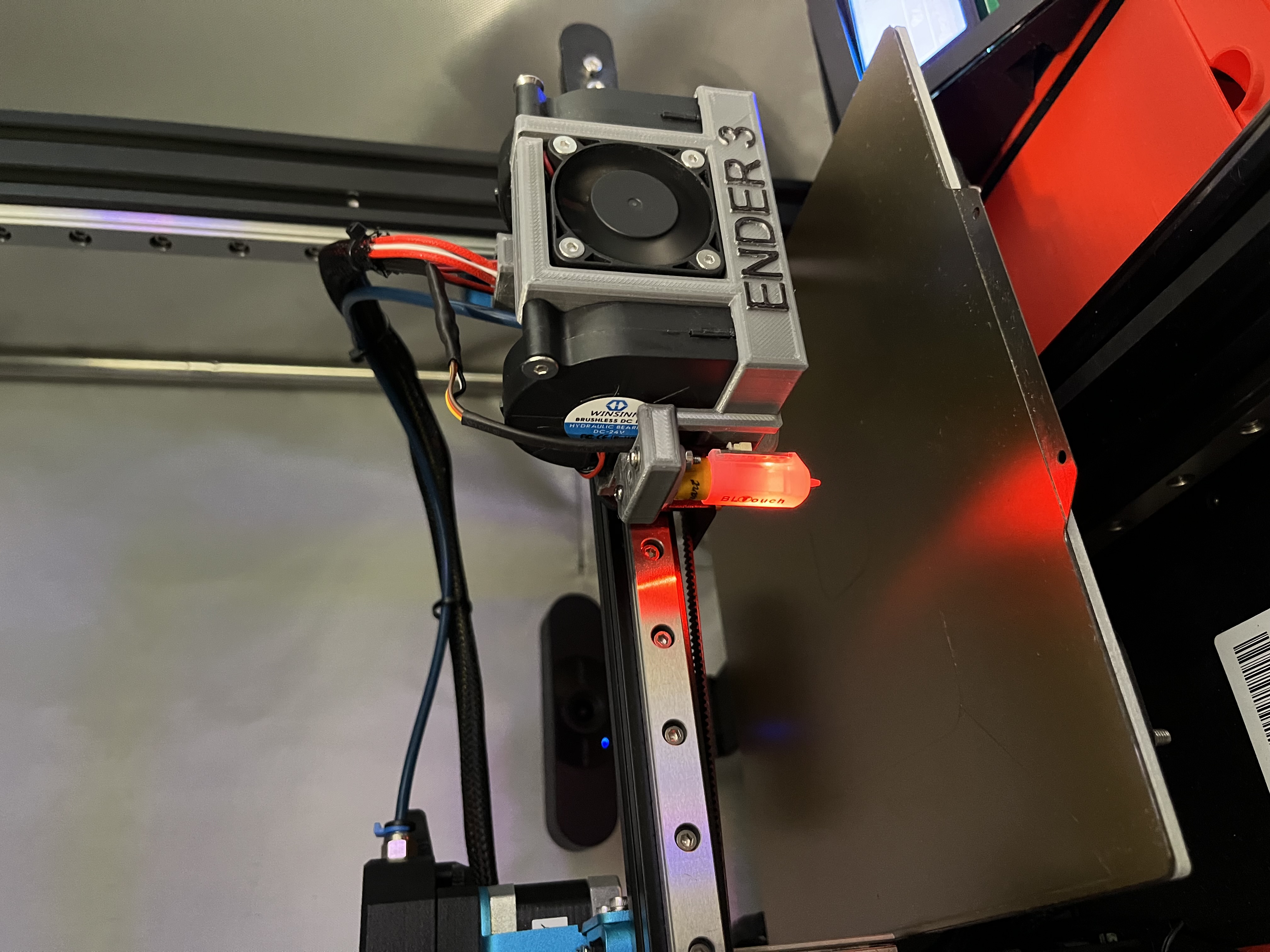

- A custom extruder head was designed to replace the original metal extruder head to lighten the weight of the X-axis while also allowing for better part cooling capacity as the printer speed increased.

- The original hot end lined with bowden tube was replaced for an all metal hot end allowing for higher print temperatures and increased speed.

Hardware and Software.

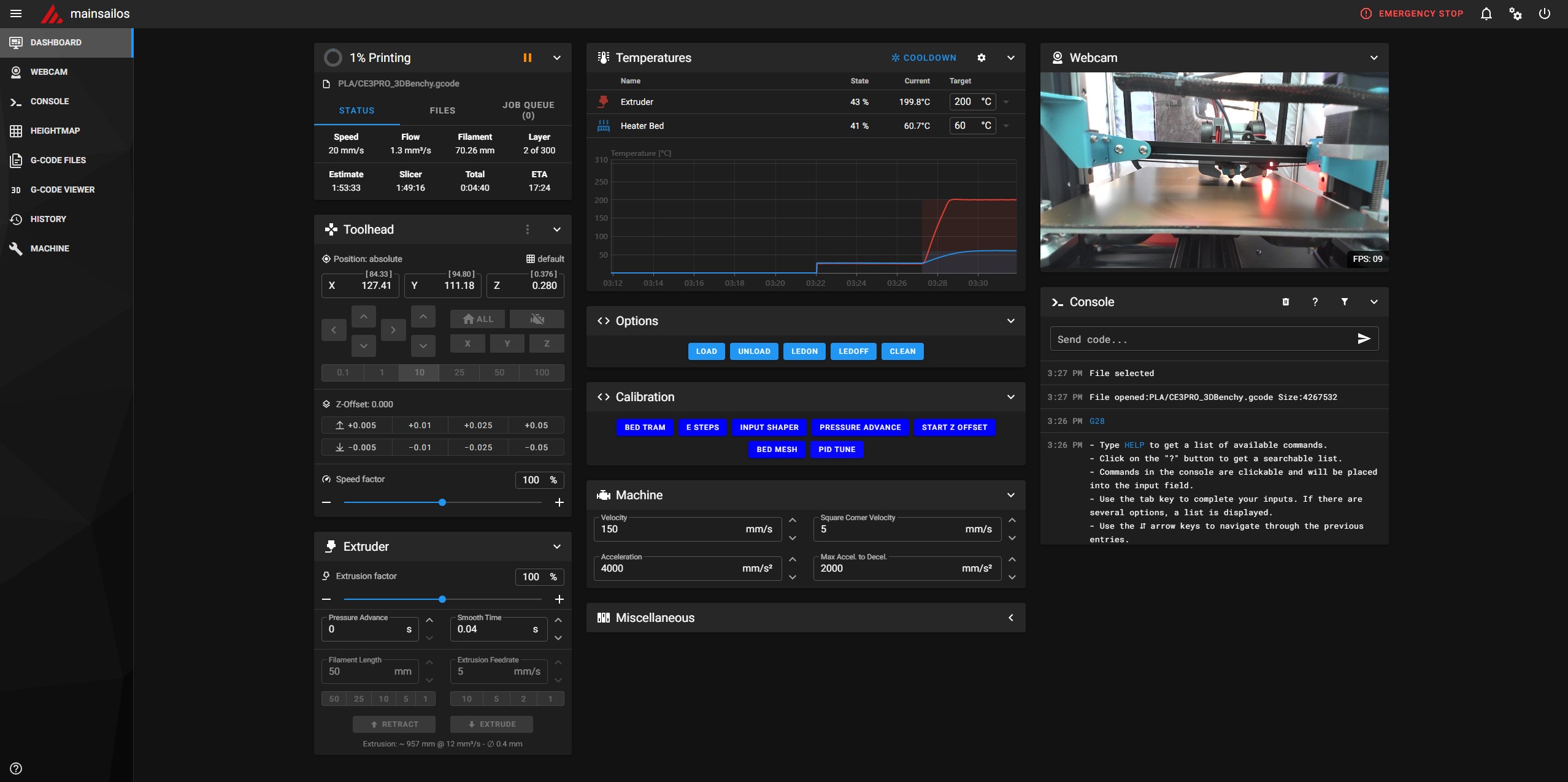

To support this newly imagined layout I wrote custom klipper firmware that ran on a raspberry pi 3. The raspberry pi sent g-code commands to the host control board to access all hardware in the printer over can bus. The new setup aimed to:

- Integrated PID control over the bed and hot end thermistors.

- Apply vibration compensation with an accelerometer.

- Apply bed leveling compensation with a BLtouch probe.

- Create a webserver to control, monitor, and update the printer.

- Use the raspberry pi for the grunt work g-code coordinate conversions and free up processor power on the host control board to allow for better print resolution.

The result is a printer that is far more robust, fast, and integrated. This allows a user to upload a file, hit print, and forget without the headache of print problems.

If you made it this far check out the original ender 3 pro and see if you can spot the differences.